Welding Inspector Near Me Things To Know Before You Get This

Table of ContentsMore About Welding Inspector Near MeHow Welding Inspector Near Me can Save You Time, Stress, and Money.The Definitive Guide for Welding Inspector Near MeThe Ultimate Guide To Welding Inspector Near Me4 Easy Facts About Welding Inspector Near Me Shown

Understanding of exactly how to measure the different weld high quality needs making use of specialized weld determines and so forth. Standard knowledge of Non Destructive Screening (NDT) demands as well as abilities. While the data base is important to get approved for welding examiner jobs, equally as vital is having the appropriate individuality for the task.The pressure positioned on welding assessors by production workers when a Does Not Comply (DNC) call is made can be really substantial. If you experience stress and anxiety when needing to withstanding strong willed individuals, this may not be the job for you. If this does not phase you, after that this element of the welding inspector work should not create you excessive tension.

A case in point being CSWIP in the UK. One more company that is taking a leading role globally in the qualification of workers for welding inspector work is the International Institute of Welding. (IIW) The International Institute of Welding is really fairly an old company, however its influence on the qualification side of things is in fact only quite recent.

By "mainstream" I imply: AWS accreditations, EWF certifications, IIW accreditations CSWIP certifications The declaration above is instead generalized, therefore it is best for you to make certain which qualifications are identified in the jurisdiction that you desire to work in. If you want to function internationally, after that generally certifications from any one of the organizations listed above would certainly certify you for welding inspector work.

The Buzz on Welding Inspector Near Me

API 1104: This is tailored in the direction of pipe welding. Usage relatively commonly, although pipe codes do often tend to have a more local bias. Many of the a lot more neighborhood pipeline welding codes are freely based on API 1104, so an excellent basis to have.

It is utilized internationally, however the major usage is in Europe. While the codes over are great starting factors, there are various different codes, standards and also specs that the welding assessor will certainly require to get an understanding of. These criteria deal with topics as diverse as welding consumables, base products, destructive as well as non-destructive testing methods, high quality management systems and so forth.

You get to understand the base codes, and after that you practically be familiar with the others with "at work" training for many years. The specific standards as well as codes hing on your particular market. The broader direct exposure you obtain to codes as well go to this website as standards, the much better a welding examiner you will certainly be.

The 5-Second Trick For Welding Inspector Near Me

Quality Equipments Understanding Central to the job of the welding examiner is the high quality guarantee as well as control function. This is not only based on technical welding expertise, however additionally top quality systems knowledge. Within this part of your job you will get to deal a whole lot with quality administration system requirements such as the ISO 9000 collection of standards, as well as likewise the ISO 3834 collection of criteria.

The Welder, Fate Compass: Weekly e-zine Subscription.

Aesthetic evaluations look for problems in the weld such as splits as well as pits. The assessor utilizes magnifying to find flaws that potential damage the stamina of the joint. Examiners measure welded products to ensure that they fulfill specs for dimension. The certified weld inspector makes use of anxiety devices to my review here place tension on weld joints.

Everything about Welding Inspector Near Me

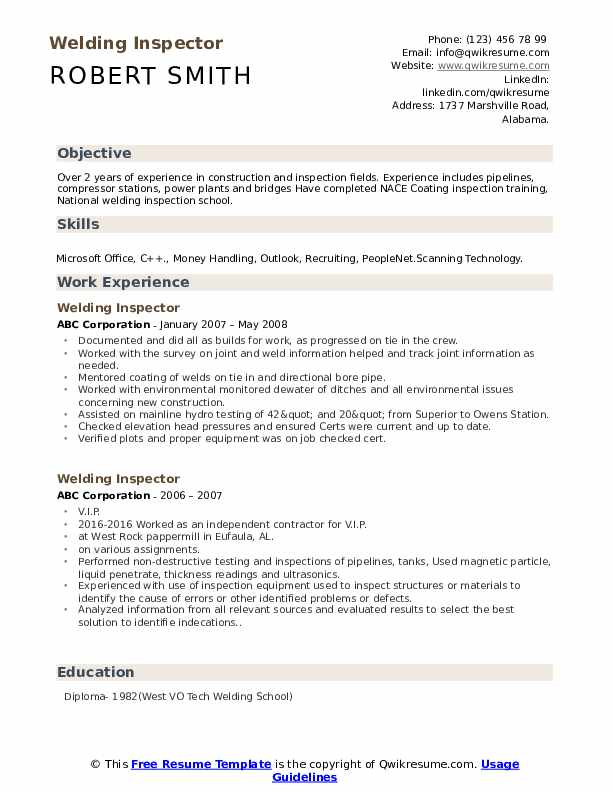

Examiners additionally examine weld equipment configuration and the welding strategies of welders on job in development to ensure the top quality of the job. Welding inspectors videotape the outcomes of tests and also welding inspections. Credentials, Employers might call for a senior high school education for a qualified welder setting. A college education and learning is not needed for many welding or welding assessment positions, but an associate level in welding innovation can Homepage improve the chances of landing a job. Welding Inspector Near Me.

Automation does not minimize the need for assessment.

Senior Staff Designer, National Board This write-up was originally published in the Fall 2009 National Board BULLETIN as the first of a two-part collection. Keep in mind: The purpose of this article is to give assessors with a basic understanding of weld inspection.

Get This Report about Welding Inspector Near Me

While not imperative, the assessor needs to find out to review common weld symbols such as the AWS symbols. At the minimum, the examiner ought to constantly bring a referral overview to analyze weld icons. Having actually reviewed all this information in advancement, the examiner will be prepared to acknowledge any type of issues as they develop rather than after-the-fact.

The producer or repair work organization (certificate owner) has suggested on duty drawing that a weld joint is to be prepared with a 60-degree bevel and origin void of 1/16 inch. Unless the bevels are crushed on accuracy machinery, it is doubtful they will certainly attain a specific 60-degree bevel as shown.